Installation Guidelines

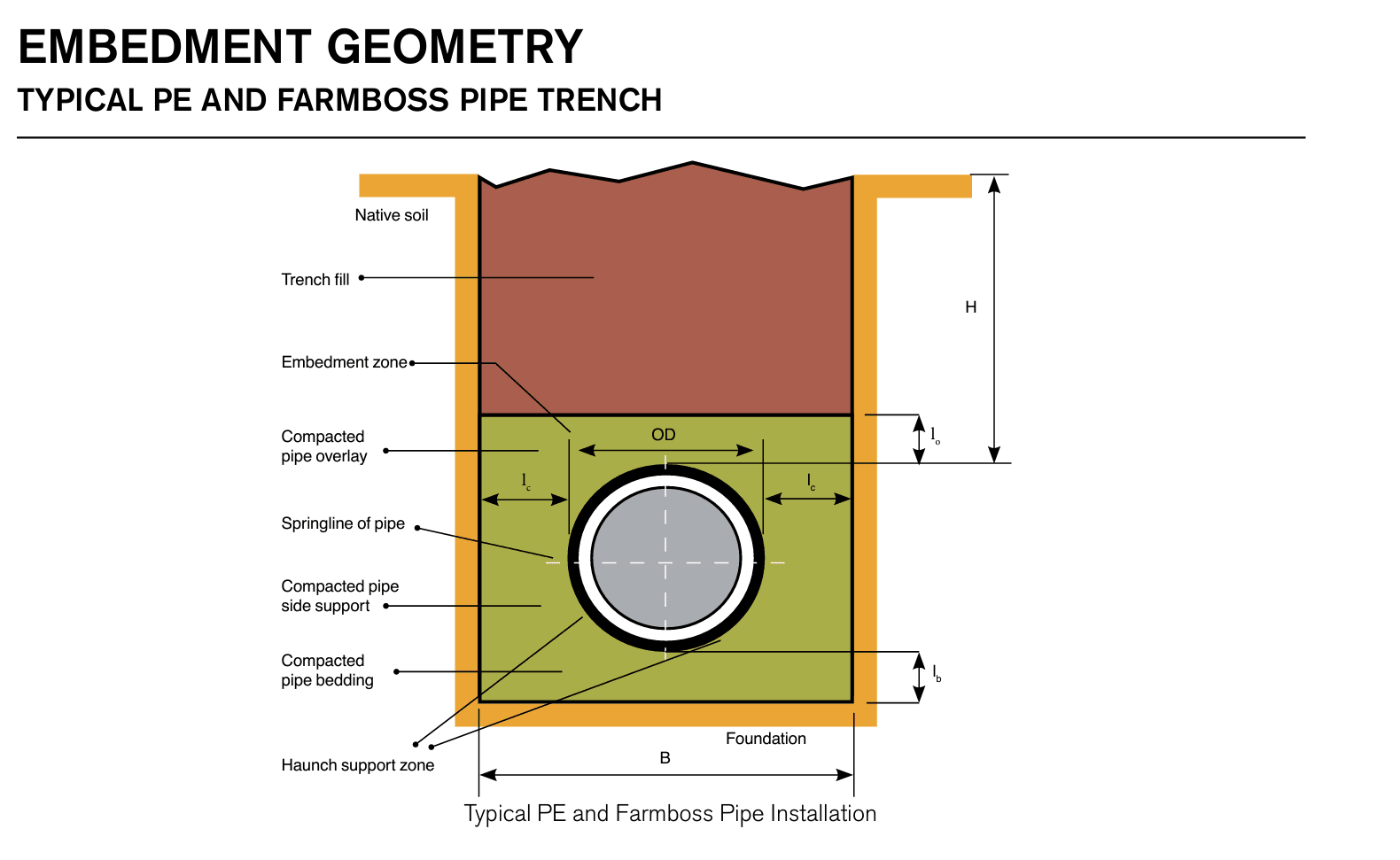

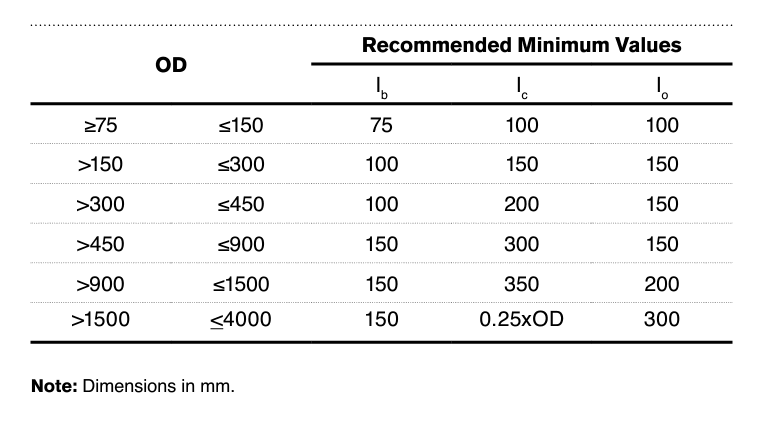

Installation practices for buried flexible pipelines are in AS/NZS 2033 and AS/NZS 2566.2 (AS/NZS 2566.1 provides guidelines for structural design). Recommended by the standard minimum dimensions of embedment zone and of the trench are detailed in the tables below, so as a general guideline:

FarmBoss®: Recommended Minimum Trench Width (B)

- DN 225: 0.56 m

- DN 300: 0.75 m

- DN 375: 0.84 m

- DN 450: 1.13 m

- DN 500: 1.17 m

- DN 600: 1.27 m

- DN 700: 1.37 m

- DN 800: 1.49 m

- DN 900: 1.69 m

- DN 1000: 1.82 m

- DN 1100: 1.93 m

- DN 1200: 2.07 m

- DN 1400: 2.37 m

- DN 1500: 2.55 m

- DN 1600: 2.81 m

- DN 1800: 3.00 m

- DN 2000: 3.33 m

- DN 2500: 4.19 m

Embedment Material

The embedment of buried flexible pipes in normal soil should be of granular compactible material, free from rocks and other hard or sharp objects, with the maximum particle size of 20 mm, preferably in the particle size range of 14 mm, and free from organic material that can affect pipe performance. To ensure good support to the bedding, side supports are constructed compacting the embedment material in layers of not more than 150 mm, or half the pipe diameter, whichever is greater.

Supaduct® Rural Installation Guideline

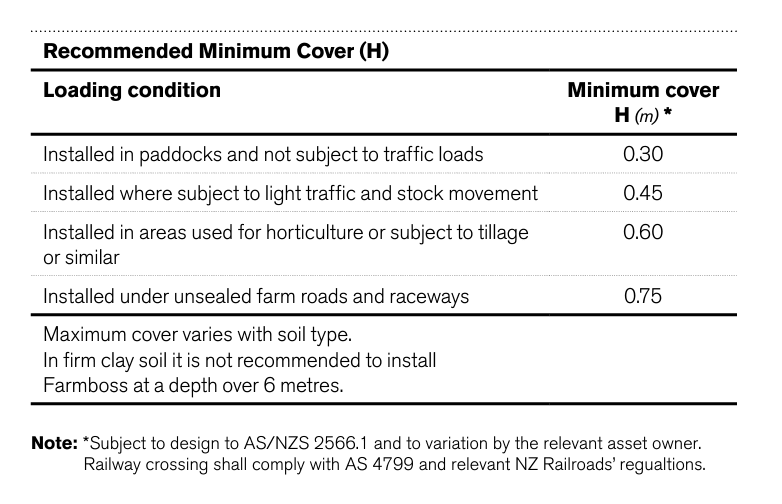

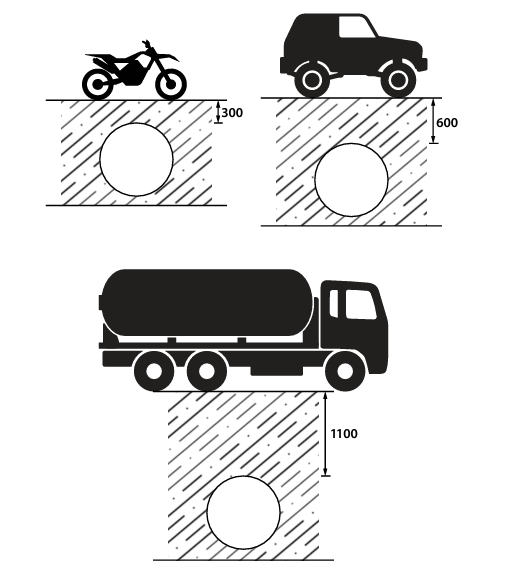

The Supaduct® Rural pipes all have a minimum ring stiffness strength of SN4. The pipes are designed to handle varying vehicle loads and soil cover heights for everyday use on farms and temporary civil works. The Supaduct® Rural pipes can handle the following settings:

- Light vehicle loading, such as motorbikes, requires a minimum of 300mm of compacted cover.

- Standard vehicle loading, such as cars, 4WD trucks and light tractor mowers, requires a minimum of 600mm of compacted cover.

- Heavy vehicle loading, such as tractors and excavators, requires a minimum of 1,100mm of compacted cover.

Determining the Trench Width and Compaction Details

When installing the supaduct® Rural pipes it is important to allow enough room either side of the pipe to compact the soil sufficiently in 300mm layers, and the table below is to be used as a minimum guideline.

Pipe Trench Width

The main reasons flexible pipes require a wide trench is to ensure compaction equipment can fit next to the pipe to get well compacted soil to help the pipe handle the load being put onto it by any vehicles.