Catching the 'brown stuff' before hitting the sea. From frozen foods to high-tech machinery, when working on a wharf and needing to clean out commercial shipping containers, it doesn't give you much space to manage waste down and stormwater run-off.

With a very high potential to spill into this very popular tourist natural seaside location and working on a commercial high capacity/traffic wharf, there is very little room for error or to fit suitable wash down and stormwater treatment device/s.

This container washdown facility, where commercial shipping containers are washed down and out after being unloaded, is then consigned to go onto the next customer. These containers can have super high levels of contaminants from plastic pellets, loose material of varying shapes, sizes and types, to hydrocarbons, food waste, insects and even dead animals (carcasses). The water from the wash down area/s (incl. debris) then flows through a diversion valve which directs the runoff water between sewer and stormwater. When washing down is happening the diversion valve is open to the sewer and directs all contaminated run-off through the Hynds Heavy Duty Oil & Grit chamber which manages this run-off and is then allowed out through the council sewer / trade waste system.

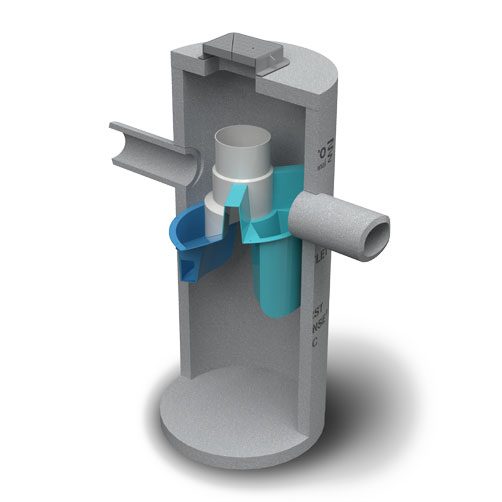

To install a Hynds heavy-duty Oil & Grit unit as well a 1200mm dia. FDHC to capture debris from the washdown water is regarded as a ‘plug and play’, meaning these units come complete to the site and are ready to drop into place, hook up pipework and backfill. This simple and practical approach to stormwater/contaminated runoff makes for a preferred solution saving time and labour onsite. The Hynds new Heavy Duty Oil & Grit units are made from their standard manholes (with all the internals fitted) and being of 2 smaller units makes placement on site much easier and safer.

As the Hynds stormwater systems are typically supplied as ‘plug & play’ these types of installs can be done in a matter of hours

When there is no washdown occurring, the diversion valve is closed and any runoff from the site (e.g. from a rain/storm event), must then pass through Hynds First Defence High Capacity unit (FDHC) before passing out to the approved council stormwater system and out to sea and is much cleaner than before. The FDHC is one of the best GPTs (gross pollutant trap) currently on the NZ market with no moving parts to wear out, no need for power supply and works 24/7 without human intervention i.e. during lockdown.

The ease and speed to deal with the Hynds Stormwater team together with their ‘plug & play’ approach to their units (which works so well) while also being very cost-effective, makes working with Hynds the ideal solution.

The Hynds FDHC is a gross pollutant trap (GPT) and can take in multiable pipes, even of different sizes and angles to process stormwater to a very high standard.

Designed to process up to 80% removal of TSS (Total Suspended Solids) down to 75 microns (the average human hair is 99 microns).

Advantages

• Cope with much higher flows

• Can receive flow from directly above the chamber

• Bypass high flows internally

• Accept multiple inlets and at differing invert depths

• Accept larger pipe diameters

• Store floatables & settled solids

• Be retro-fitted into existing chambers

Maintenance of these GPTs (FDHC) is a big question as ongoing costs will affect their installation decision and costs. The Hynds FDHC is super easy to clean with no internal access (confined space) normally needed, where a sucker truck simply pulls up beside (over) the unit, lifts the manhole cover and drops their cleaning hoses down into the device. Time on-site needed for cleaning of the interior is typically within the hour.