How stormwater discharge requirements were exceeded for a medium density residential development on Creyke Road, Christchurch, New Zealand.

Prompt and accurate conveyance of roof and carpark run off is vital to prevent localised flooding in urban areas and poses a major challenge to all Councils. Often Engineers are required to meet strict attenuation criteria to alleviate increased volumes due to urban intensification.

Traditionally above, or below ground tanks are used with a basic reduced orifice outlet to slowly discharge flow over time. Often, the size of the orifice is sized conservatively meaning excessive storage and heightened risk of blocking. This case study overviews the novel future-proofed approach that Engineering Consultancy Kirk Roberts designed in order to exceed Council requirements and Developer preferences.

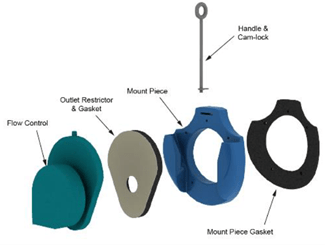

The Hydro-Brake® Optimum is the only vortex flow control for which the head and discharge relationship can be fine-tuned to optimise your design. Designers can size a Hydro-Brake® to achieve the perfect hydraulic performance curve and engineer the best possible passive flow control performance.

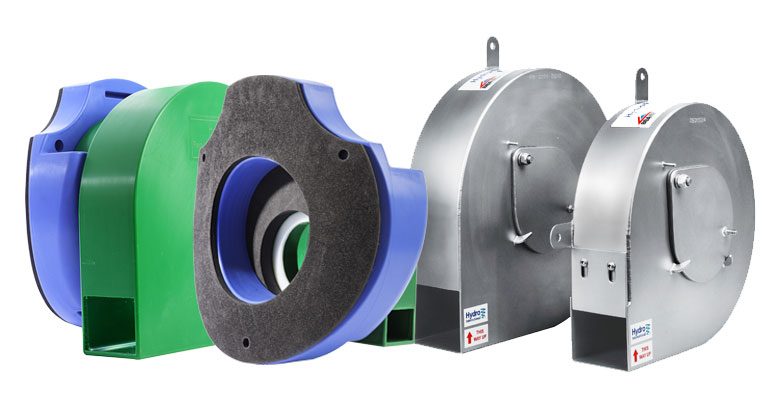

Hydro-brakes can be supplied in either 316 Stainless Steel (SS) or Polyethylene (PE) depending on the application (generally for stormwater or sewer). The 316 SS option is custom-made whereas the PE option (up to 20L/s) is stocked in NZ. The PE option can also be supplied with a curved or flat backing plate in the small or large size depending on the diameter of the concrete chamber that encases it.

OVERVIEW

The Creyke Road development consists of 800m2 of carparking and 1,200m2 off roofing which during a 5mm/hr rain event generates approx. 2.5L/s. Due to the location of the development and the capacity of the receiving SW network, a maximum discharge limit of 1.6L/s was required.

Water Sensitive Urban Design (WSUD) targets were met with the inclusion of a suitably sized detention basin which receives all roof water from the site. This detention basin serves as upstream storage when the Hydro-Brake® is in operation. From there the roof water is piped to the Hydro-Brake® flow regulating manhole located within the property boundary prior to discharging into the Council network. All carpark runoff is directed to a filter.

APPROACH

The first step toward specifying a Hydro-Brake® device is to enter all parameters into the online sizing tool or contact your local Hynds Representative.

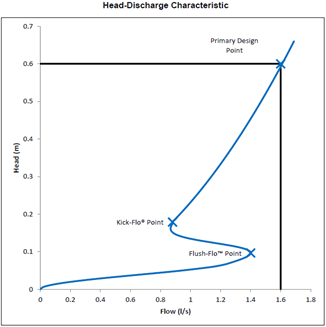

In most cases the design head and discharge flow rate are the two main inputs seen in the below table. A graph is then generated to illustrate the expected flow characteristics.

| TECHNICAL SPECIFICATION | |

| Design Head | 0.6 m |

| Design Flow Rate | 1.6 L/s |

| Flush Flo Head | 0.1 m |

| Flush Flo Flow Rate | 1.4 L/s |

| Kick Flo Head | 0.18 m |

| Kick Flo Flow Rate | 0.88 L/s |

| Mean Flow Over Head | 1.17 L/s |

| Orifice diameter | 58 mm |

The below graph shows that as rain begins to fall and enter the Hydro-Brake®, the Flush Flo flow rate of 1.4L/s is achieved very quickly with very little resistance. As head continues to increase in the manhole the flow regulating vortex begins to form thus throttling flow. Once the vortex is stable at the Kick Flo point, flow and head increase until the design point is met. At this stage, the discharge flow rate of 1.6L/s will be fixed; meaning the upstream detention basin will increase in head.

INSTALLATION

Armed with the Hydro-Brake® drawings from the Consultant Engineer, the device can be supplied from any Hynds Branch. Being PE in this case, the Contractor arranged the outlet orifice plate to be accurately core-drilled to 58mm.

The backing plate (pictured in blue) was then fastened over the outlet of the flow control manhole; with the Hydro-Brake® (green) designed to easily slid into position. Inspection is made easy with the handle being located directly beneath the cast iron manhole cover allowing for easy removal.

CONCLUSION

It is widely agreed that climate change will bring about added flood risk in urban areas due to increased intensity and frequency of storm events. As a measure to accurately control stormwater runoff a Hydro-Brake® was successfully installed at a medium density development in Christchurch, NZ. Monitoring over the past 12 months reveals that the device is operating exactly as intended.